CHD

Introduction

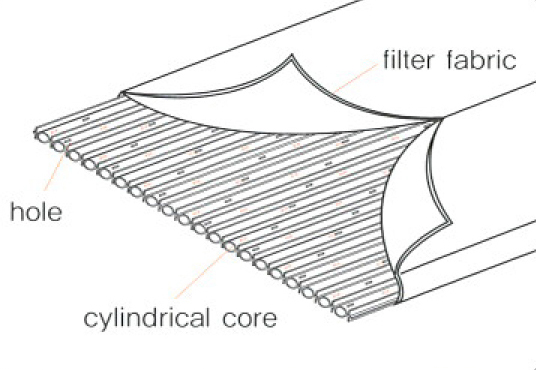

CHD(Cylindrical Horizontal Drain)is a fully filtered, prefabricated subsoil drainage system widely used around world. It consists of a plastic inner ribbed double core overwrapped with a geotextiles filter fabric. CHD is placed under the surcharge to receive the flow from the vertical drains and conduct it laterally to discharge points at the edge of the surcharge. In most cases the installation of CHD is less expensive than a granular or sand drainage blanket.

Shape and type

CHD 200

CHD 300

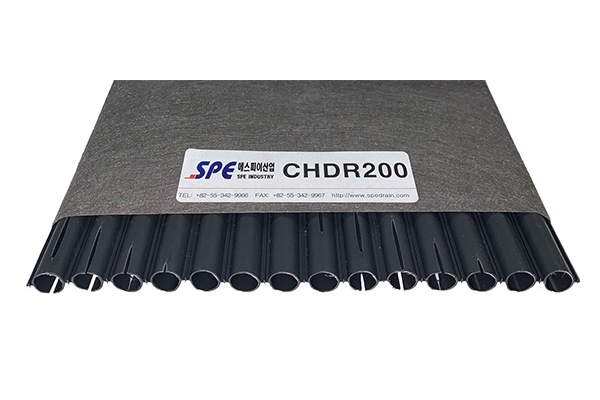

CHDR 200

CHDR 300

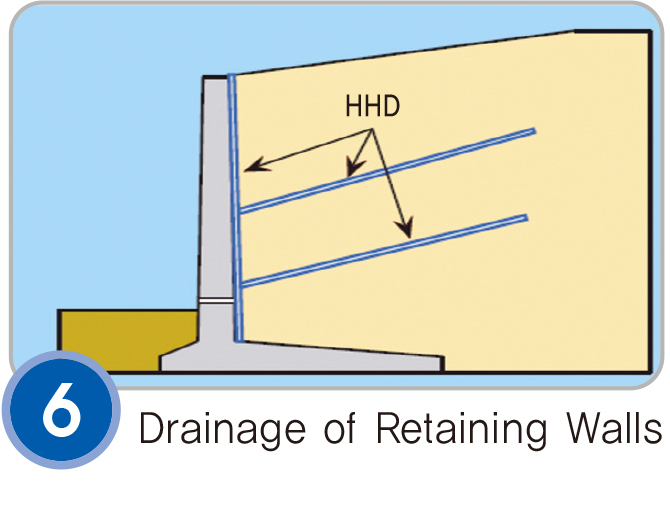

HHD

Introduction

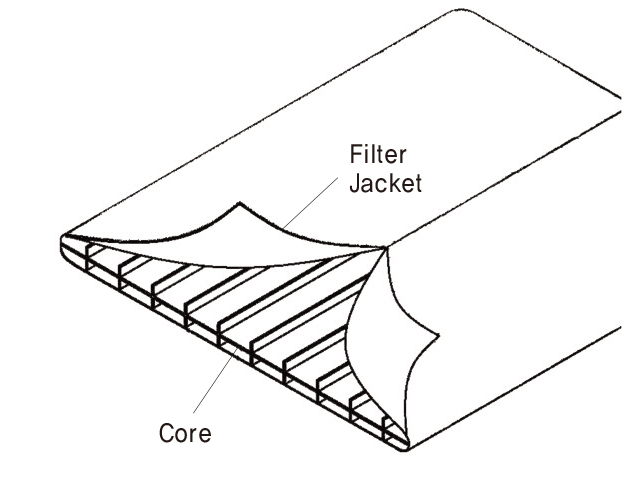

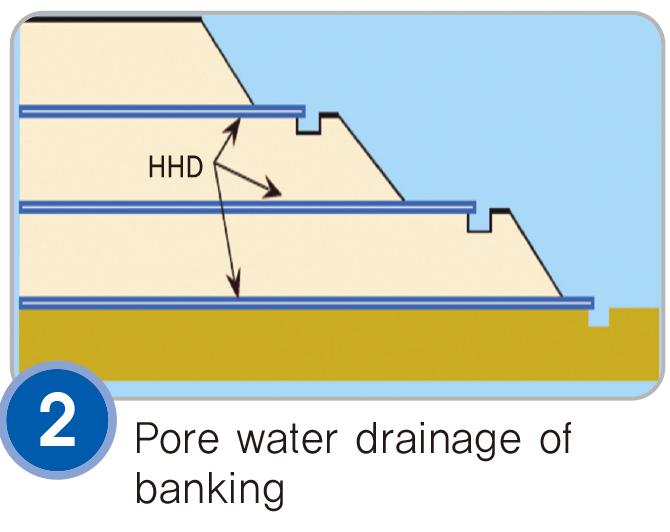

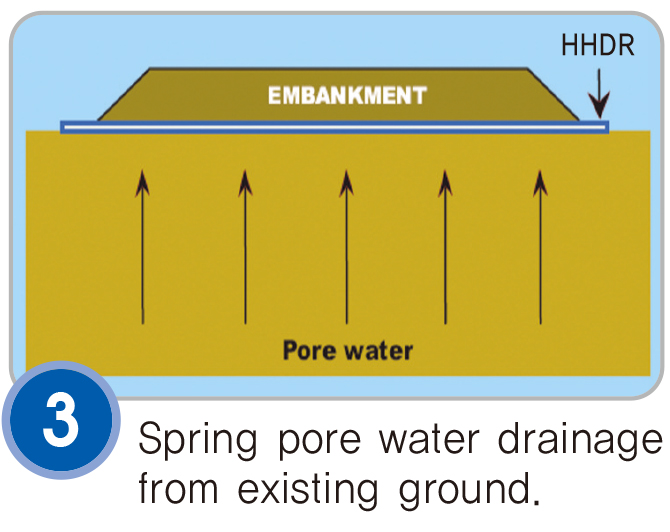

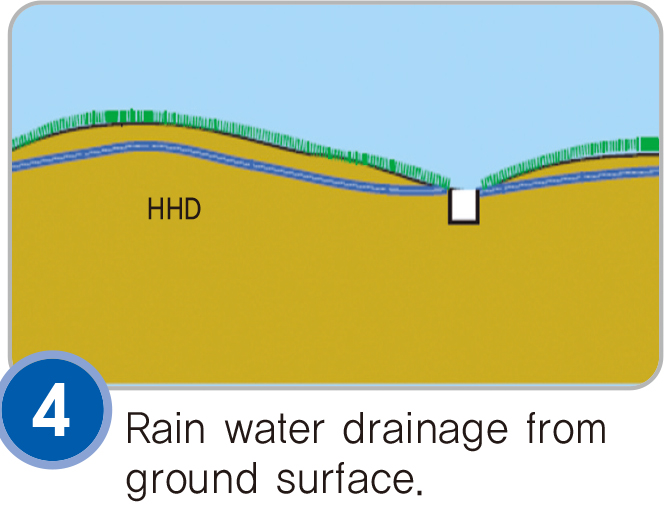

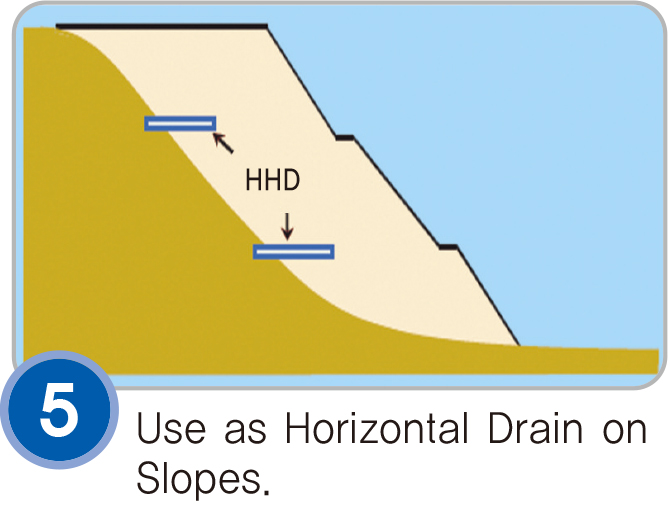

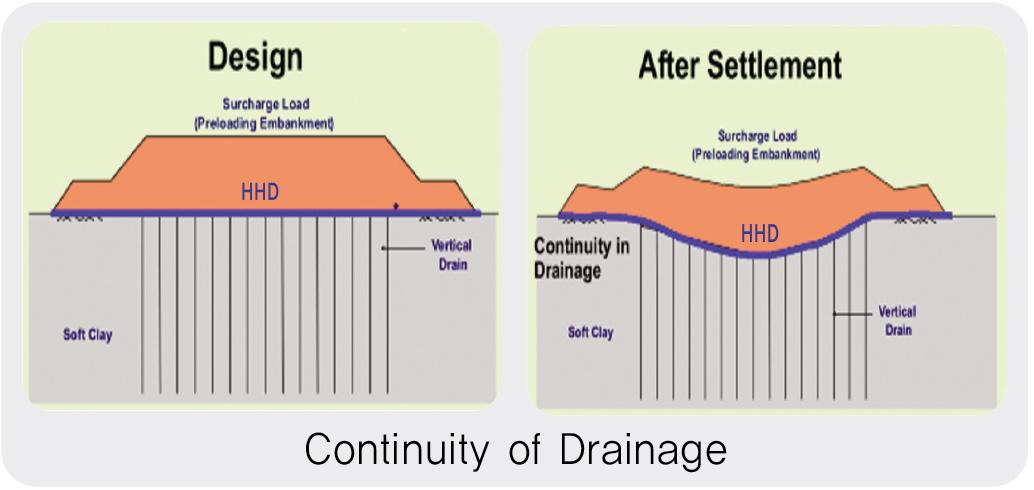

HHD(Harmonica type horizontal drain) is a fully filtered, prefabricated subsoil drainage system widely used around world. It consists of a plastic inner Harmonica core overwrapped withageotextiles filter fabric. HHD is placed under the surcharge to receive the flow from the vertical drains and conduct it laterally to discharge points at the edge of the surcharge. In most cases the installation of HHDR is less expensive than a aggregate or sand drainageblanket.

Shape and type

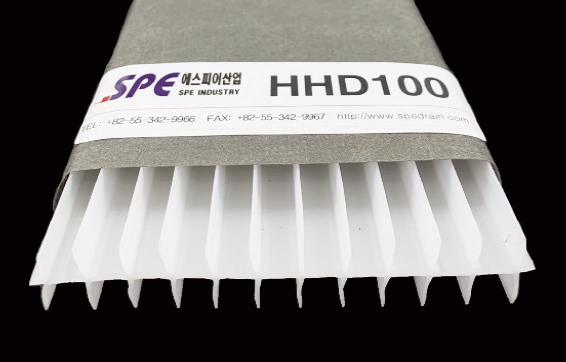

HHD100

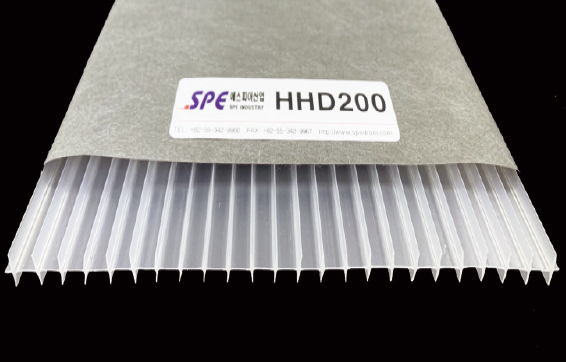

HHD200

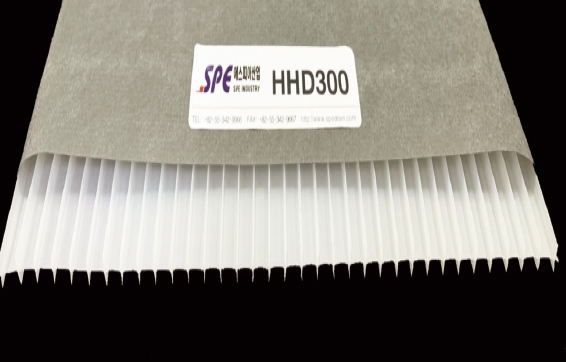

HHD300

HHDR100

HHDR200

HHDR300

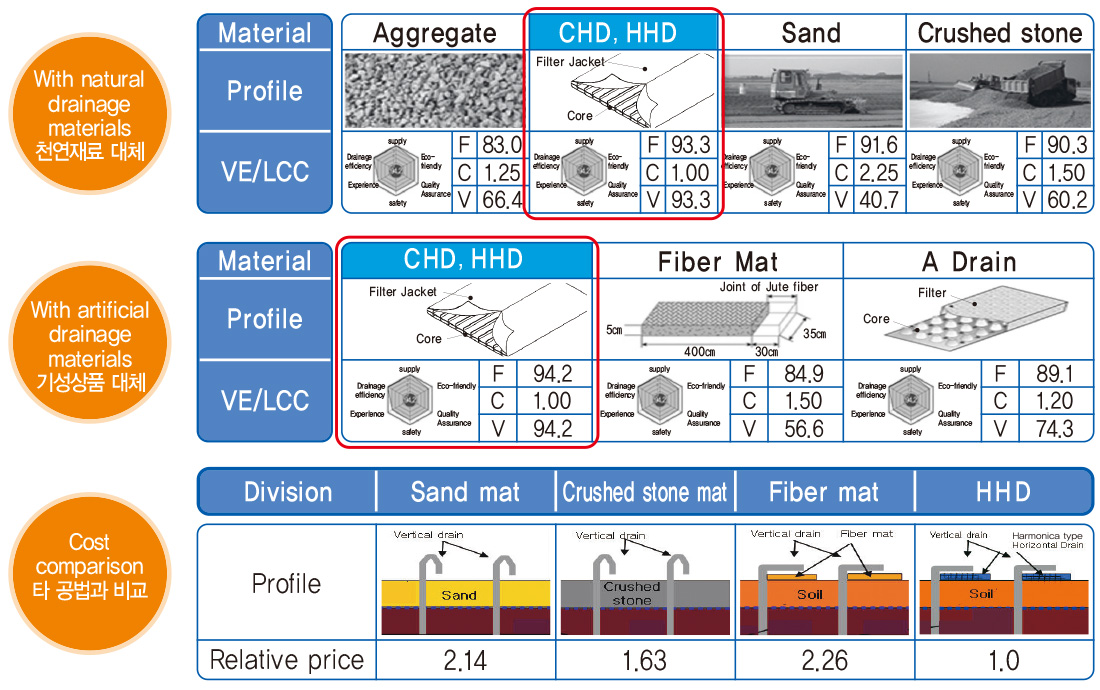

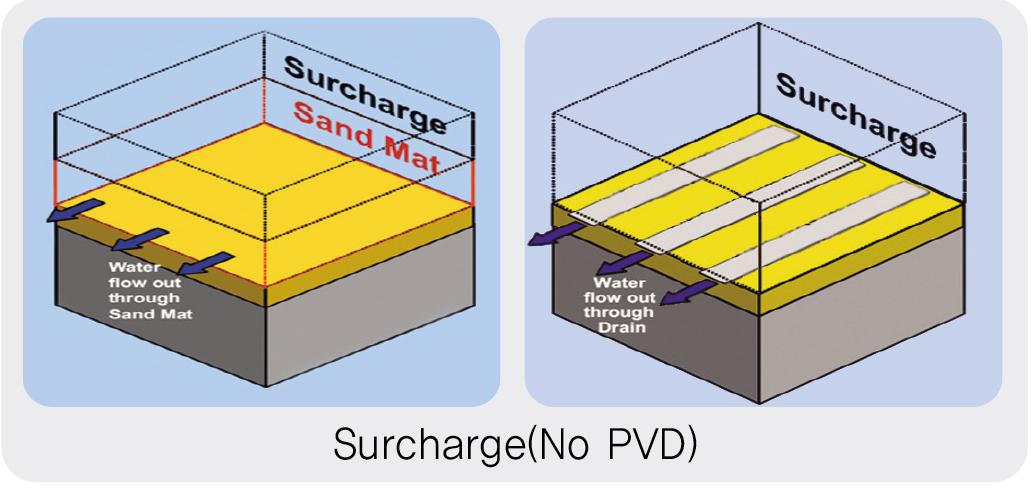

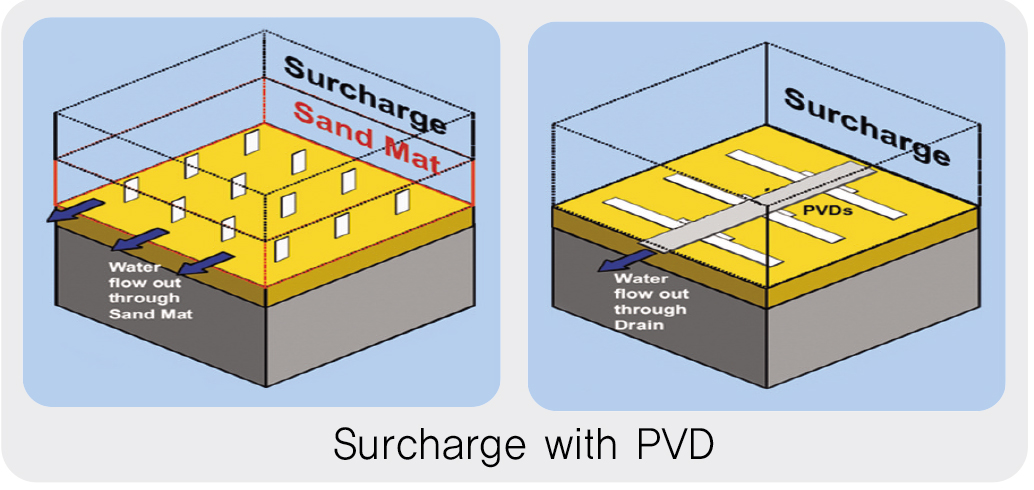

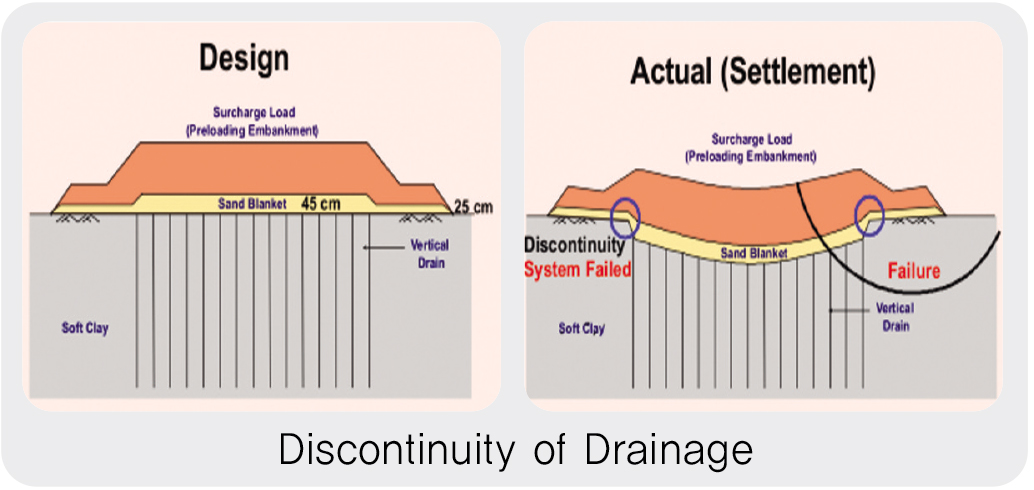

Comparison of horizontal drainage method

Benefit

- 1Low cost

- Installation and material cost is half than gravel or sands

- Easy to store and transport.

- 2High Drainage efficiency

- Structure of core provides multiple channels for vertical and horizontal water flow.

- Filter fabric permits high volume entry of water into core while restraining soil particles.

- 3Workability

- Lightweight, flexibility easy-to-handle

- No heavy equipments or skilled laborers are required.

- 4Confidence

- Uniform properties and quality assure predictable drain performance.

Application

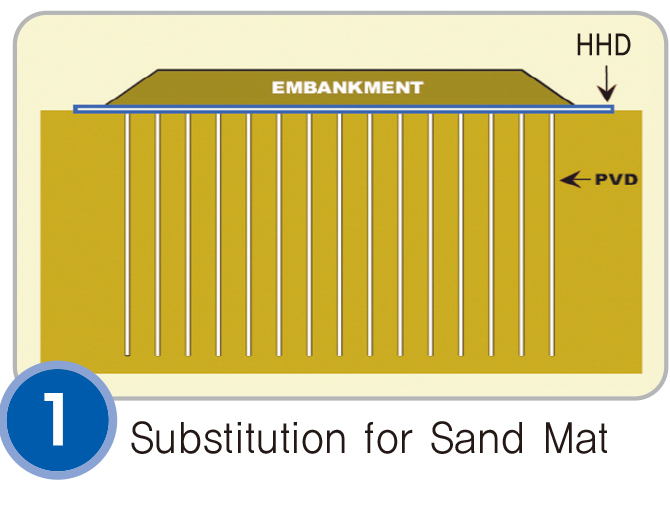

Substitution for sand mat

The improvement of soft ground

Road construction

Sand mat

HHD

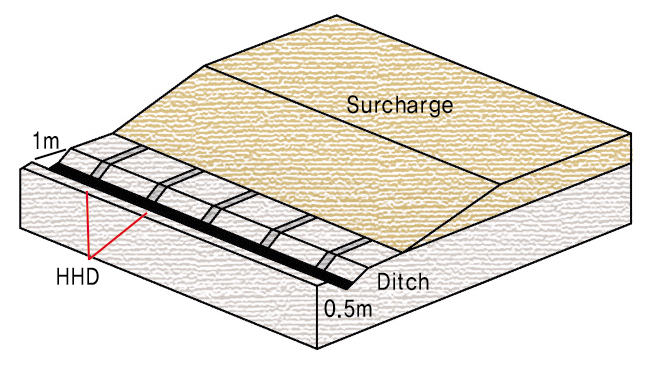

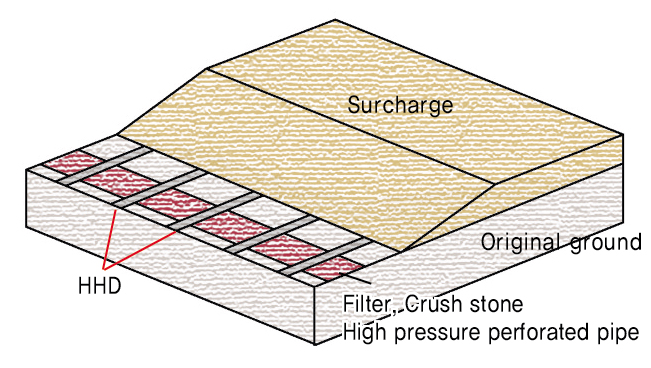

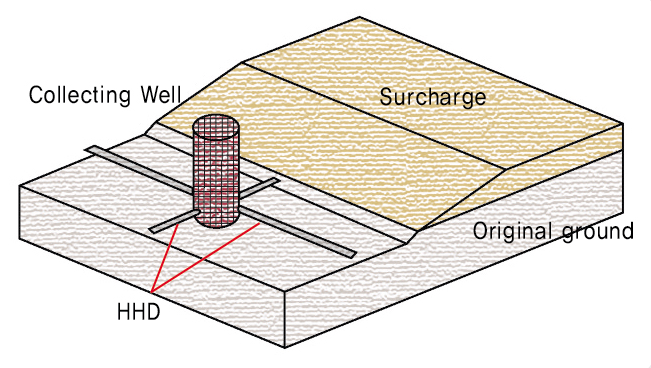

Collecting water method with HHD

Ditch

Filter, Crush stone, High pressure, Perforated pipe

Collecting well

Method of installation

Original ground

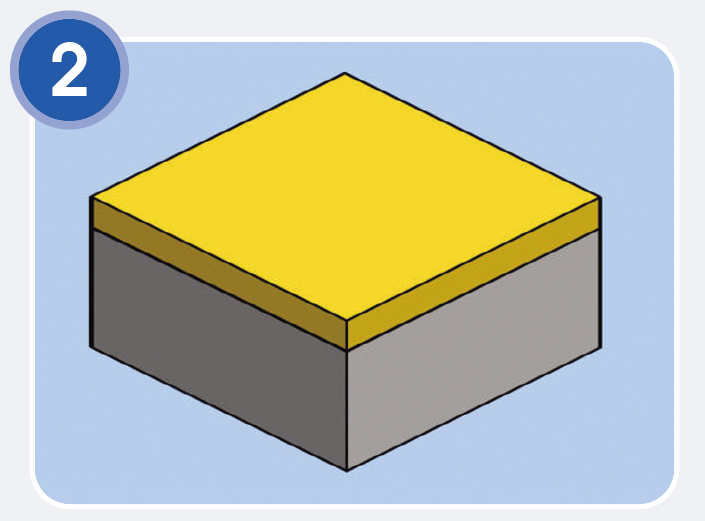

Place Platform

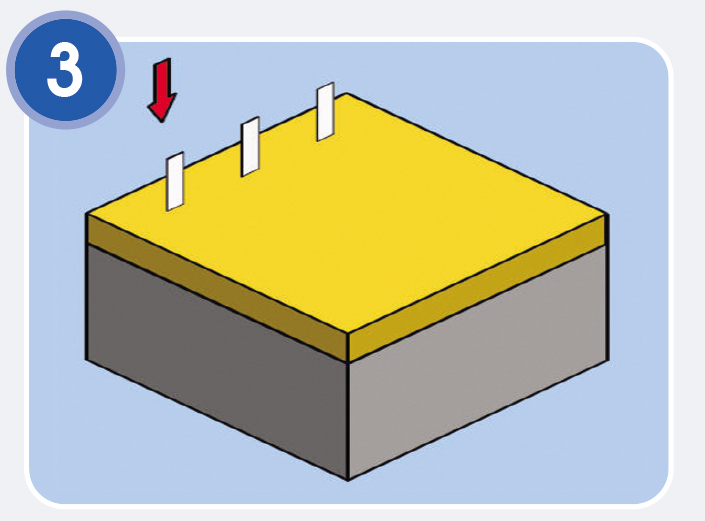

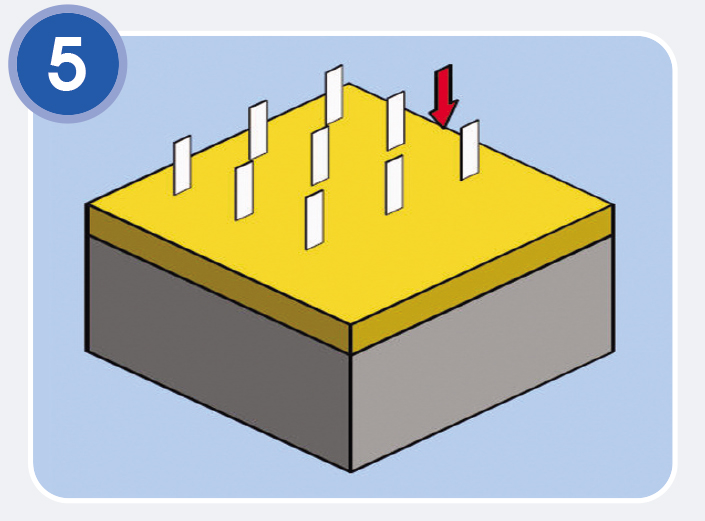

Inastall 1st row PBDs

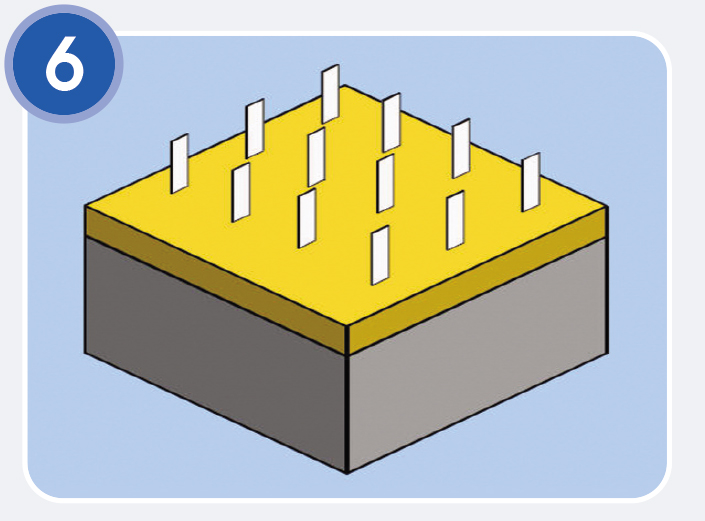

Inastall 2nd row PBDs

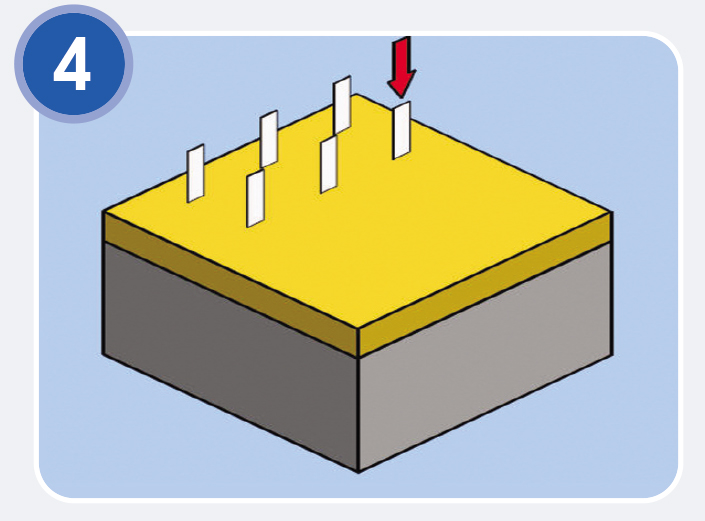

Inastall 3rd row PBDs

Inastall 4th row PBDs

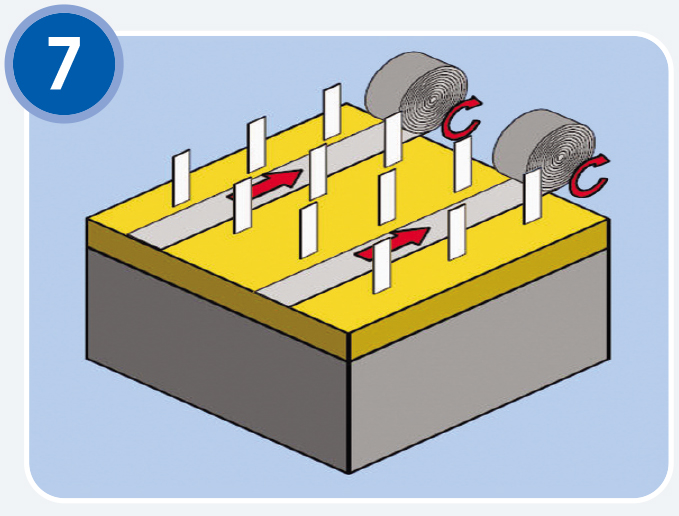

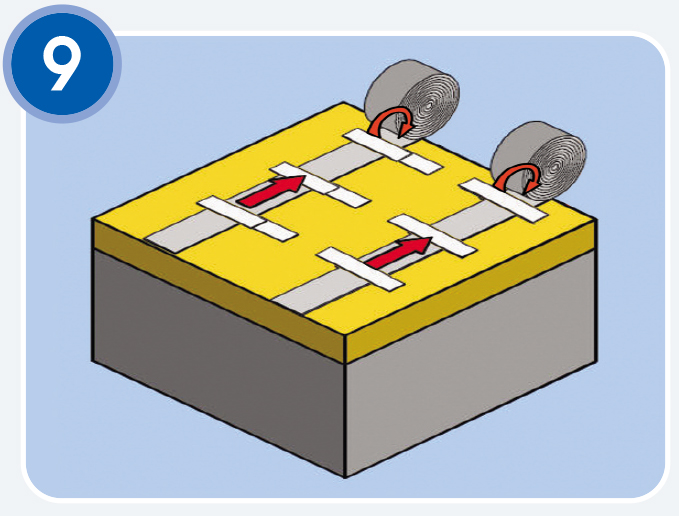

HHDR Install

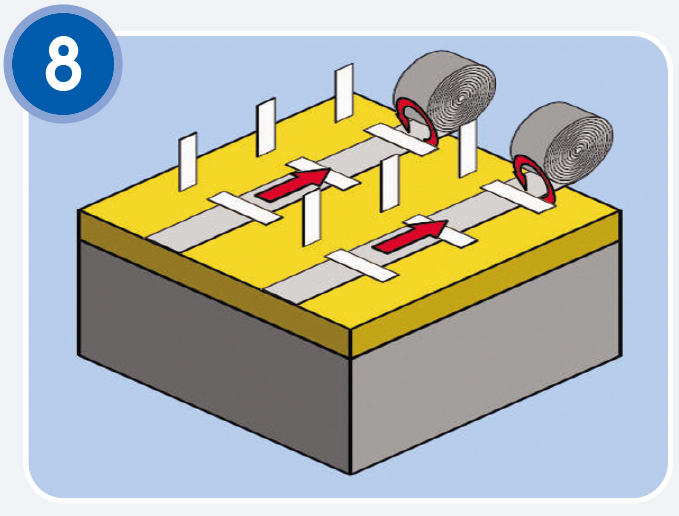

Fold 2nd & 4th row PBDs

Fold 1st & 3rd row PBDs

Staple PBDs to HHDR

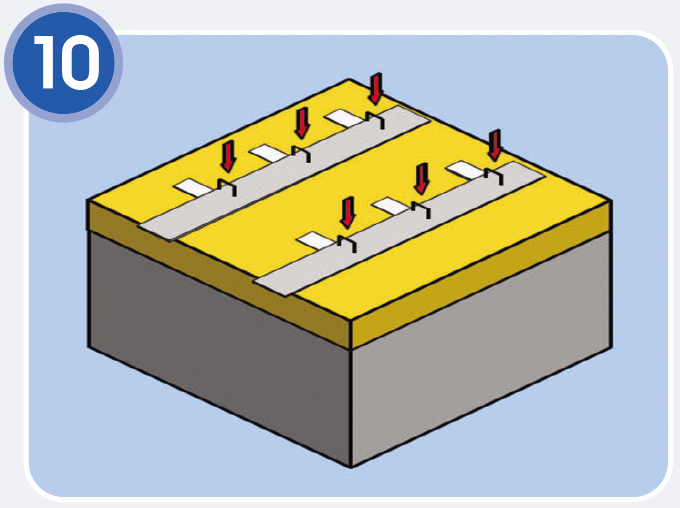

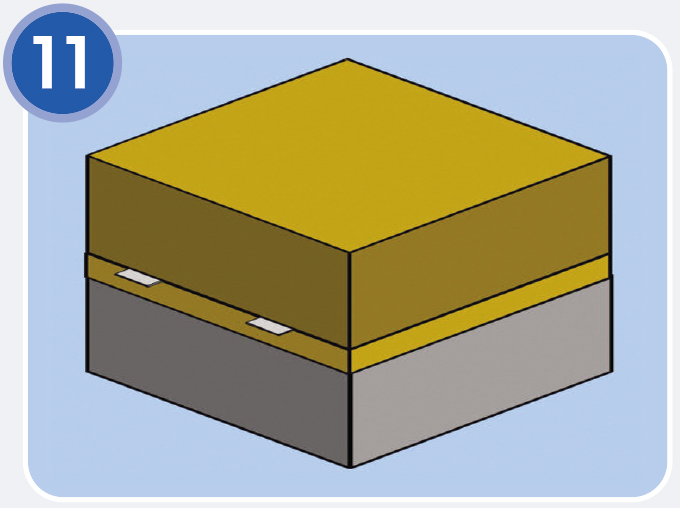

Place surcharge

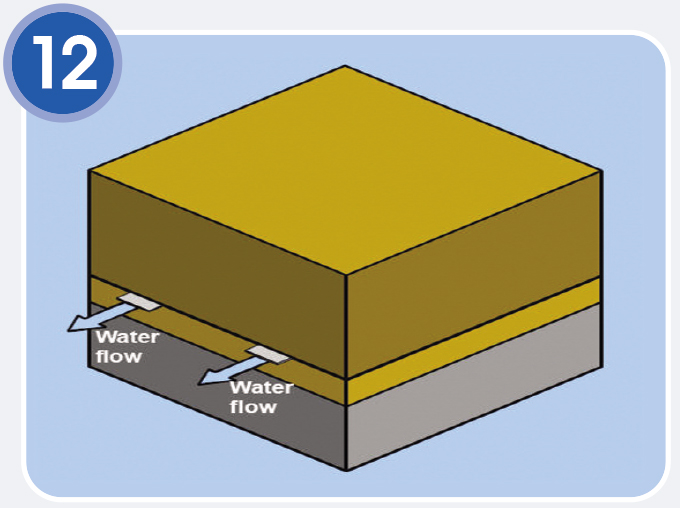

Water drainage

Photos

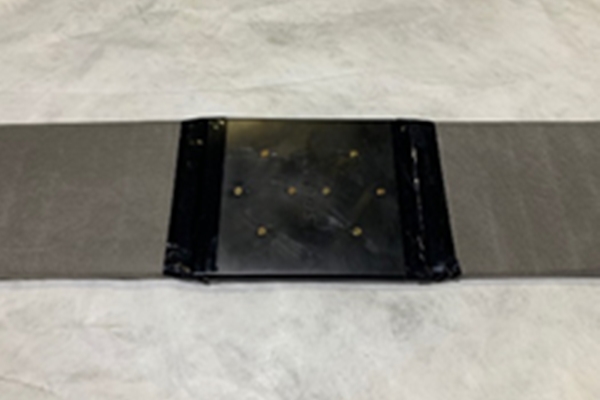

Connector

Introduction

In connecting drain boards (PHD) (when installing on soft ground), the Connector is used. When connecting boards, the Connector enables connecting two drain boards seamlessly. The Connector uses a stapler to prevent connected drain boards from being disconnected due to tension. In addition, the Connector reduces material expenses by reducing losses and provides eco-friendly function by removing a source of environmental damage.

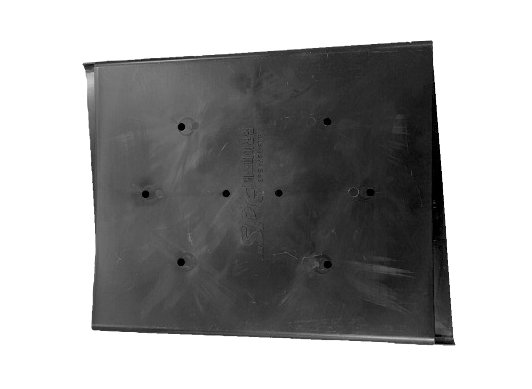

Shape and type

100 Joint

200 Joint

300 Joint

Benefit

- 1Ease of insertion of drainboard with insertion groove

- 2Balanced insertion induction between products with a stopper in the center of the product.

- 3Prevent cutting of joints due to constant tension

- 4Thickness of the product side is thin, giving it flexibility when it is burned.

- 5Reduce material costs by making the connection easy and eliminating the need to dispose of remaining parts

- 6Continuous drainage is possible by connecting the drain space of the drain board, leading to excellent drainage effects.

- 7Eliminate environmental degradation factors at source

Connecting method

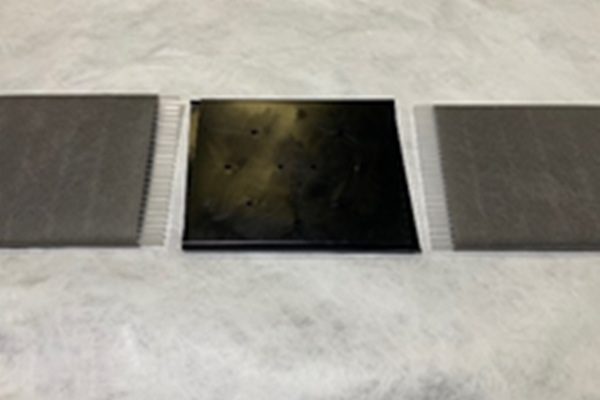

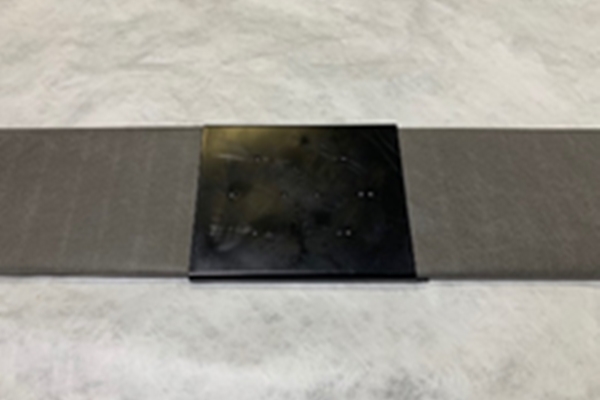

1.End of Horizontal Drain

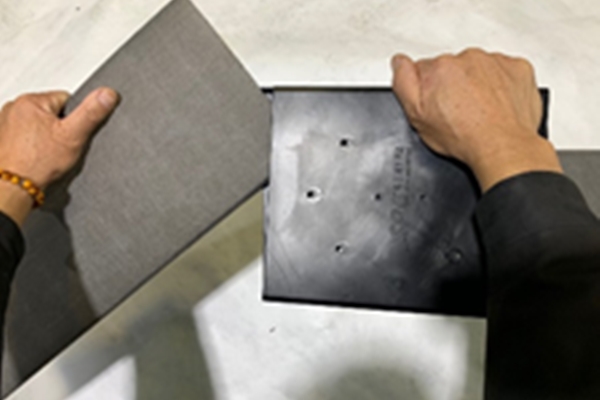

2.Insert by guide on end of connector

3.Inserted into one side of connector

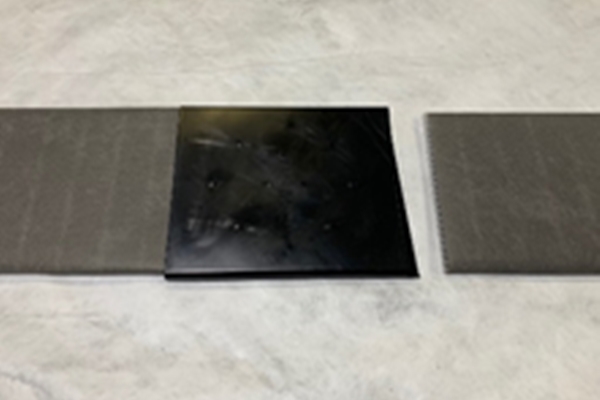

4.Inserted both sides of connector

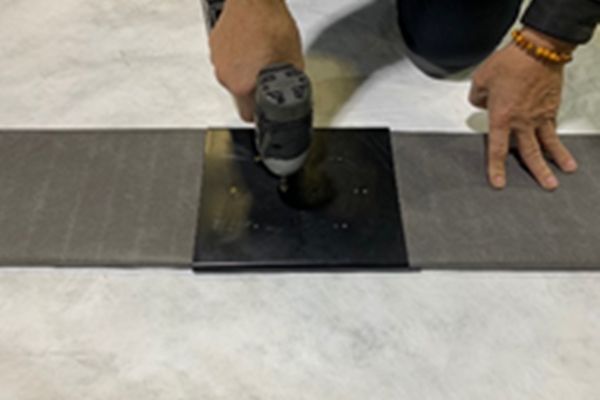

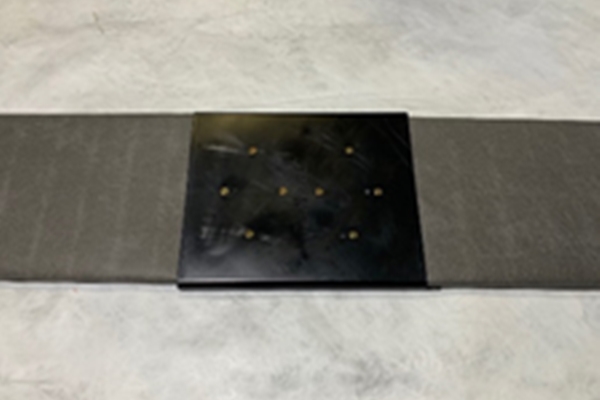

5.Fasten with screws

6.Fastened with 8 crews (4 each side)

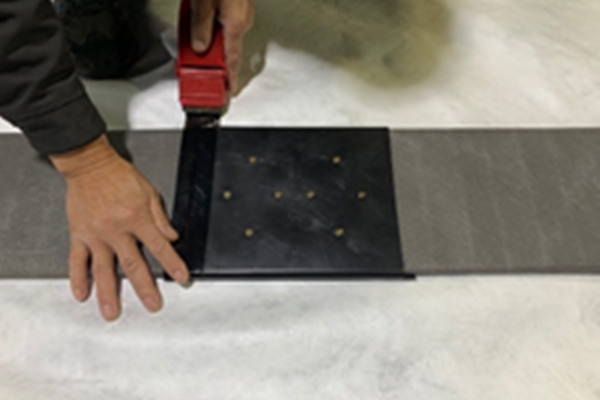

7.Taping both end of connector

8.Connection finished

CHD

CHD HHD

HHD Connector

Connector